Berridge Siding A Comprehensive Guide

Berridge siding offers a compelling blend of aesthetics and durability for your home’s exterior. This guide delves into every aspect of Berridge siding, from its material composition and installation process to its long-term maintenance and environmental impact. We’ll explore the various design options, cost considerations, and troubleshooting tips to help you make an informed decision about whether Berridge siding is the right choice for your next home improvement project.

Whether you’re a homeowner looking to enhance your curb appeal or a contractor seeking detailed installation instructions, this comprehensive resource provides valuable insights into the benefits and considerations associated with Berridge siding. We’ll cover everything from choosing the perfect color and finish to understanding the environmental implications and addressing potential maintenance issues.

Berridge Siding

Berridge siding offers a durable and aesthetically pleasing exterior cladding option for homes. This section delves into the material composition, manufacturing process, durability, maintenance, and available finishes of Berridge siding.

Berridge Siding Material Composition and Properties

Berridge siding, while a brand name, typically refers to a type of engineered wood siding. The exact composition can vary slightly depending on the manufacturer and specific product line, but generally consists of a composite material made from wood fibers, resins, and other additives. These additives enhance the siding’s resistance to moisture, insects, and decay. The resulting product is a strong, lightweight, and relatively easy-to-install material. The specific blend of materials contributes to the overall performance characteristics, such as its resistance to warping, cracking, and fading.

Berridge Siding Manufacturing Process

The manufacturing process for Berridge-style engineered wood siding typically involves several steps. First, wood fibers are combined with resins and other additives. This mixture is then formed into the desired shape and size using extrusion or other molding techniques. The formed siding is then cured under controlled conditions to ensure proper bonding and strength. Finally, the siding undergoes a finishing process that may include priming, painting, or applying a protective coating. This process ensures a consistent and durable final product. The exact manufacturing techniques and materials may differ based on the specific brand and product line.

Durability of Berridge Siding Compared to Other Materials

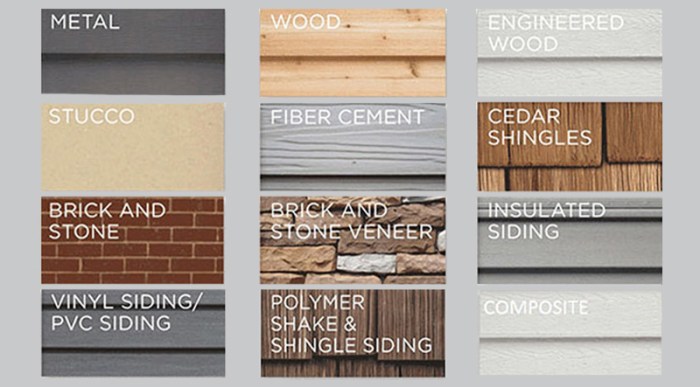

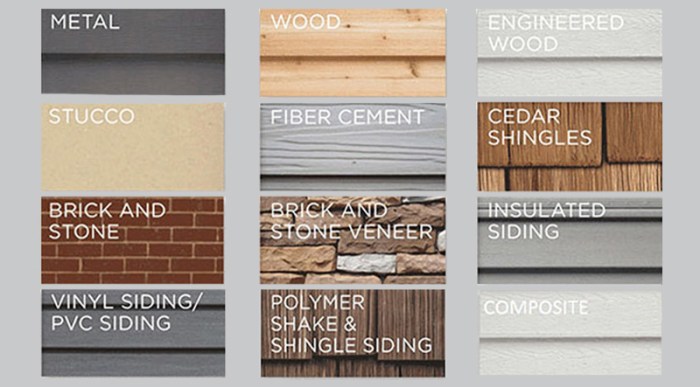

Berridge siding’s durability is comparable to, and in some aspects surpasses, other common siding materials. Compared to vinyl siding, engineered wood siding often offers superior resistance to impact damage and dents. While vinyl can fade over time, engineered wood siding with proper protective coatings can maintain its color for longer. Compared to wood siding, engineered wood offers significantly improved resistance to rot, insect infestation, and moisture damage, requiring less maintenance. Fiber cement siding, while also durable, can be more brittle and susceptible to cracking than engineered wood siding. The longevity of Berridge siding, like other siding types, is dependent on proper installation and maintenance.

Berridge Siding Maintenance Requirements

Berridge siding generally requires minimal maintenance. Regular cleaning with water and a mild detergent is usually sufficient to remove dirt and debris. Inspecting the siding periodically for any signs of damage, such as cracks or loose pieces, is also recommended. Promptly addressing any damage will prevent further issues and extend the lifespan of the siding. Unlike wood siding, Berridge siding does not typically require regular painting or staining, reducing the long-term maintenance burden. However, specific maintenance instructions may vary depending on the finish and protective coatings applied to the siding.

Berridge Siding Finishes and Colors

A wide variety of finishes and colors are available for Berridge-style engineered wood siding, allowing for customization to match different architectural styles and personal preferences.

| Finish Type | Color Options | Maintenance Needs | Estimated Lifespan (Years) |

|---|---|---|---|

| Smooth | White, Beige, Gray, Brown, Black | Occasional cleaning | 30-50 |

| Textured | Various earth tones, wood grains | Occasional cleaning | 30-50 |

| Wood Grain | Cedar, Oak, Redwood | Occasional cleaning | 30-50 |

| Painted | Wide range of custom colors | Repainting as needed (every 10-15 years) | 30-50 (depending on paint quality and maintenance) |

Berridge Siding

Source: emmonsroofing.com

Berridge siding offers a durable and aesthetically pleasing exterior cladding option for homes. Its installation, while manageable for DIY enthusiasts with some experience, benefits from careful planning and execution. Understanding the process, associated costs, and comparative pricing against other siding materials will ensure a successful and cost-effective project.

Berridge Siding Installation Process

Installing Berridge siding involves a series of steps, beginning with proper preparation and ending with final finishing touches. First, the existing siding must be removed, and the underlying sheathing inspected for damage. Any necessary repairs, such as replacing rotten wood or patching holes, should be completed before proceeding. Next, a weather-resistant barrier, such as house wrap, is installed to protect the home’s structure from moisture. Then, the starting course of Berridge siding is installed, ensuring proper alignment and levelness. Subsequent courses are then added, overlapping each previous course according to the manufacturer’s instructions. Finally, trim pieces, such as J-channel and corner pieces, are installed to complete the look and protect the edges of the siding. Proper fastening is crucial throughout the process to ensure a secure and long-lasting installation.

Surface Preparation for Berridge Siding

Thorough surface preparation is paramount for a successful Berridge siding installation. This involves removing any old siding, cleaning the underlying surface, and repairing any damaged areas. Inspect the wall sheathing for rot, insect damage, or loose boards. Replace any damaged sections with new, appropriately treated lumber. Ensure the sheathing is smooth and level, using shims as needed to correct any unevenness. Clean the surface thoroughly to remove dirt, debris, and any loose paint or other materials that could interfere with adhesion. A properly prepared surface ensures the siding adheres correctly and prevents future problems.

Factors Influencing Berridge Siding Installation Cost

Several factors influence the overall cost of a Berridge siding installation. The size of the project is a major determinant, with larger homes naturally requiring more materials and labor. The complexity of the project, such as the presence of numerous angles, dormers, or other architectural features, also increases costs. Material costs, which can vary depending on the type of Berridge siding chosen and current market prices, are another key factor. Labor costs, which are influenced by the local market rate for skilled labor and the project’s complexity, significantly impact the overall price. Finally, the need for additional services, such as demolition of existing siding or repairs to the underlying structure, will add to the expense.

Comparison of Berridge Siding Installation Costs to Other Siding Options

The cost of Berridge siding installation is competitive with other mid-range siding options. While it may be more expensive than vinyl siding, it generally offers superior durability and longevity. Compared to more expensive options like cedar or brick, Berridge siding provides a cost-effective alternative without sacrificing aesthetic appeal. The actual cost comparison depends heavily on the specific materials and labor costs in a given region and the size and complexity of the project. It’s advisable to obtain multiple quotes from different contractors to compare pricing accurately.

Sample Budget Breakdown for Berridge Siding Installation

A realistic budget should account for several key cost components. This example assumes a medium-sized home (approximately 1500 square feet) with average complexity.

- Materials: $8,000 – $12,000 (This includes Berridge siding, underlayment, fasteners, and trim)

- Labor: $6,000 – $10,000 (This depends on the contractor’s rates and the project’s duration)

- Permits and Inspections: $500 – $1,000 (These costs vary by location and project requirements)

- Waste Removal: $200 – $500 (This covers disposal of old siding and construction debris)

- Contingency: $1,000 – $2,000 (This accounts for unexpected costs or changes)

Total Estimated Cost: $15,700 – $25,500

Note: This is a sample budget and actual costs may vary significantly depending on location, project specifics, and contractor selection. Always obtain multiple detailed quotes from reputable contractors before making any decisions.

Berridge Siding

Source: mammablog.org

Berridge siding offers a versatile and attractive option for homeowners seeking to enhance the exterior of their homes. Its durability and aesthetic appeal make it a popular choice for a variety of architectural styles and design preferences. This section will explore the design and aesthetic aspects of Berridge siding, providing guidance on its application and integration with other building materials.

Architectural Styles Compatible with Berridge Siding

Berridge siding’s adaptability allows for seamless integration into numerous architectural styles. Its clean lines and varied texture options make it suitable for modern, contemporary, farmhouse, craftsman, and even traditional homes. The choice of color and installation pattern significantly influences the overall aesthetic, allowing for customization to match the specific architectural style. For instance, a crisp white Berridge siding with board-and-batten installation would complement a classic farmhouse design, while a darker gray tone with a horizontal lap pattern would suit a modern aesthetic.

Enhancing Curb Appeal with Berridge Siding

Berridge siding significantly contributes to curb appeal through its visual impact. Strategic use of color, texture, and installation patterns can dramatically transform a home’s exterior. For example, using contrasting colors for accents, such as window trim or fascia boards, creates visual interest and emphasizes architectural details. Varying the siding pattern, such as combining vertical and horizontal planks, adds depth and complexity to the façade. Careful consideration of the home’s overall proportions and the surrounding landscape is crucial for maximizing the positive impact of the siding.

Integrating Berridge Siding with Other Building Materials

Berridge siding integrates well with a wide range of materials, creating visually appealing and cohesive exteriors. It complements stone, brick, stucco, and wood accents beautifully. For instance, a combination of Berridge siding on the main body of the house and stone accents around the base or near the entryway creates a classic and sophisticated look. Similarly, combining Berridge siding with wood trim and accents can evoke a rustic or craftsman style. The key is to maintain a balanced and harmonious design, ensuring the materials complement each other rather than clash.

Visual Description of a House Featuring Berridge Siding

Imagine a two-story craftsman-style home clad in a warm, medium-toned brown Berridge siding. The siding’s slightly textured surface gives it a rustic charm, complementing the home’s natural wood accents around the windows and porch. The windows are framed with crisp white trim, providing a striking contrast against the brown siding. A dark brown shingle roof adds to the home’s rustic aesthetic, while the landscaping features lush green lawns and mature trees, softening the home’s lines and enhancing its overall appeal. The color palette is consistent, with the brown siding, dark brown roof, and white trim creating a visually pleasing and cohesive design.

Design Considerations for Homeowners Choosing Berridge Siding

Choosing Berridge siding involves several important considerations. First, the homeowner should select a color and texture that complements the existing architectural style and landscaping. Secondly, the installation method (horizontal, vertical, or a combination) should be carefully considered, as it significantly impacts the visual appeal. Thirdly, the homeowner should factor in the long-term maintenance requirements of the siding, considering its durability and resistance to weather damage. Finally, it’s important to choose a reputable installer to ensure a professional and high-quality installation that maximizes the siding’s aesthetic and functional benefits.

Berridge Siding

Source: theiconacropolis.com

Berridge siding offers a durable and aesthetically pleasing exterior cladding option for homes. Understanding its environmental impact is crucial for homeowners committed to sustainable building practices. This section details the environmental considerations associated with Berridge siding, from manufacturing to disposal, and compares it to alternative siding materials.

Manufacturing Environmental Impact of Berridge Siding

The environmental impact of manufacturing Berridge siding stems primarily from the extraction and processing of raw materials, energy consumption during manufacturing, and transportation. The specific impact varies depending on the exact composition of the siding (e.g., the type and percentage of recycled materials used) and the manufacturing processes employed. Generally, the production of any building material involves energy use, potential air and water pollution, and the generation of waste. For example, the manufacturing process might involve the use of fossil fuels for energy, leading to greenhouse gas emissions. However, responsible manufacturers strive to minimize these impacts through energy-efficient practices and waste reduction strategies.

Comparison with Other Siding Options

Compared to other siding options, Berridge siding’s environmental footprint is highly variable. For instance, wood siding requires harvesting trees, which can contribute to deforestation and habitat loss unless sustainably sourced. Vinyl siding, while often durable, is derived from petroleum and is not readily biodegradable. Fiber cement siding, while a more sustainable alternative to vinyl, often involves the use of cement production, a process known for its high energy consumption and associated emissions. A comprehensive life-cycle assessment comparing Berridge siding’s environmental impact to these alternatives requires detailed information on the specific materials and manufacturing processes involved in each siding type. This comparison should consider factors like embodied carbon, energy consumption, and waste generation throughout the product’s lifespan.

Recyclability and Disposal Methods

The recyclability and disposal methods for Berridge siding depend on its specific composition. Some Berridge siding products may contain recycled materials, and some manufacturers may offer recycling programs for their products at the end of their life. If recycling is not an option, proper disposal methods, such as landfill disposal, should be followed according to local regulations. It is advisable to check with your local waste management authority for specific guidelines. The information on recycling and disposal should be readily available from the manufacturer.

Sustainable Practices in Berridge Siding Production

Sustainable practices in Berridge siding production can significantly reduce its environmental footprint. These practices may include using recycled materials in the manufacturing process, employing energy-efficient technologies, minimizing waste generation, and sourcing materials from responsibly managed forests. Manufacturers may also focus on reducing water consumption during production and implementing measures to control air and water pollution. The adoption of these practices contributes to a more environmentally responsible production process.

Contribution to Environmentally Conscious Homes

Choosing Berridge siding can contribute to a more environmentally conscious home, particularly if the product incorporates recycled materials and is manufactured using sustainable practices. By selecting a siding option with a lower environmental impact, homeowners can reduce their overall carbon footprint and contribute to a more sustainable built environment. This decision aligns with broader efforts towards reducing the environmental impact of construction and promoting sustainable living.

Berridge Siding

Berridge siding, while durable, can be susceptible to certain issues over time. Understanding these potential problems and how to address them is crucial for maintaining the beauty and integrity of your home’s exterior. This section will guide you through common problems, repair methods, and preventative maintenance strategies to ensure your Berridge siding remains in top condition for years to come.

Common Berridge Siding Issues

Several factors, including weather exposure, age, and impact, can lead to problems with Berridge siding. Common issues include cracking, discoloration, water damage, and fastener problems. Cracks often appear due to expansion and contraction from temperature fluctuations, while discoloration may result from sun exposure or mildew growth. Water damage can manifest as rot or warping, and loose or missing fasteners can compromise the siding’s structural integrity.

Repairing Minor Damage to Berridge Siding

Minor damage, such as small cracks or loose fasteners, can often be repaired easily. For cracks, carefully clean the area and apply a high-quality exterior-grade caulk designed for siding repair. Match the caulk color to your siding as closely as possible for a seamless finish. For loose fasteners, tighten them securely, or if necessary, replace them with new ones of the same type and size. Ensure the new fastener penetrates the underlying sheathing properly.

Addressing Specific Berridge Siding Problems

This section details step-by-step solutions for common issues:

- Cracks: 1. Clean the cracked area thoroughly. 2. Apply a thin bead of exterior-grade caulk, matching the siding color. 3. Smooth the caulk with a damp finger or putty knife. 4. Allow the caulk to dry completely before painting, if necessary.

- Discoloration: 1. Identify the cause (mildew, dirt, etc.). 2. For mildew, use a mildew remover according to the product instructions. 3. For dirt, use a soft brush and mild detergent solution. 4. Rinse thoroughly with clean water. 5. Allow the siding to dry completely before applying a protective sealant, if desired.

- Water Damage: 1. Assess the extent of the damage. 2. If rot is present, replace the affected siding section. 3. Ensure proper flashing and sealing around windows and doors to prevent future water intrusion. 4. Repair any damaged sheathing or underlying structure.

Preventative Maintenance for Berridge Siding

Regular inspection and maintenance are key to extending the lifespan of your Berridge siding. This includes cleaning the siding annually to remove dirt, debris, and mildew. Inspect the siding for any signs of damage, loose fasteners, or water intrusion. Addressing minor issues promptly can prevent them from becoming major problems. Consider applying a protective sealant every few years to help protect the siding from the elements.

Berridge Siding Inspection and Maintenance Checklist

Regular inspections are crucial for early detection of problems. Use this checklist for your annual inspection:

- Inspect all siding for cracks, chips, or other damage.

- Check for loose or missing fasteners.

- Examine areas around windows and doors for signs of water damage.

- Look for any signs of mildew or algae growth.

- Clean the siding with a pressure washer (low pressure setting) or brush and mild detergent.

- Inspect caulking around windows and doors and re-caulk as needed.

- Check the condition of gutters and downspouts to ensure proper water drainage.

- Address any identified issues promptly.

Final Summary

Source: 99.co

Ultimately, the decision to use Berridge siding rests on a careful consideration of your individual needs and preferences. This guide has provided a detailed overview of the material’s properties, installation process, aesthetic considerations, environmental impact, and potential maintenance requirements. By weighing these factors against your budget and desired outcome, you can confidently determine if Berridge siding is the ideal solution to elevate your home’s exterior and enhance its overall value.

Commonly Asked Questions

What is the warranty offered on Berridge siding?

Warranty details vary depending on the specific Berridge siding product and its installer. Check with your supplier for precise warranty information.

Can Berridge siding be installed over existing siding?

In some cases, yes, but proper assessment of the existing siding’s condition is crucial. A professional should evaluate the suitability before installation.

How often should Berridge siding be cleaned?

Regular cleaning, typically once or twice a year, using a mild detergent and water, helps maintain its appearance and longevity.

What are the common causes of discoloration in Berridge siding?

Discoloration can result from prolonged exposure to sunlight, environmental pollutants, or improper cleaning methods.

Is Berridge siding resistant to insect damage?

The level of insect resistance depends on the specific composition of the Berridge siding. Consult the product specifications for details.

Comments are closed.